Uyini umehluko phakathi kwe-screw conveyor kanye ne-spiral conveyor?

Amagama athi "isikulufo sokuhambisa" kanye ne-spiral conveyor abhekisela ezinhlotsheni ezahlukene zezinhlelo zokudlulisa, ezihlukaniswe ngomklamo wazo, indlela yokusebenza kanye nokusetshenziswa kwazo:

1. Isikulufu Sokuthutha

Indlela Yokusebenza: Isebenzisa i-helical screw blade ejikelezayo (endiza) ngaphakathi komgodi noma ithubhu. I-screw iyajikeleza ukuhambisa izinto ezinkulu (isb., izimpushana, ama-granules, udaka) ngobude bomthumeli.

Umklamo:

Ngokuvamile ivundlile noma ithambekele (kufika ku-~20–30°).

Ingafakwa umgodi (umgodi ophakathi osekela ukundiza) noma ingabi namgodi (ngezinto ezinamathelayo).

Izinto ziphushwa zingene ebhodweni elivaliwe, okuvimbela ukuchitheka.

Izicelo:

Ezolimo (ukuphathwa kokusanhlamvu), ukwelashwa kwamanzi amdaka, ukucubungula ukudla, kanye nokuthuthwa kwezinto eziningi zezimboni.

Kuhle kakhulu ekuphekeni okulawulwayo, ekuxubeni, noma ekulinganiseni izinto.

2. I-Spiral Conveyor

Indlela Yokusebenza: Ibhekisela ohlelweni lokuhambisa oluhlelwe ngendlela eqondile noma eqondile ejikelezayo/ejikelezayo, ngokuvamile kusetshenziswa amabhande, ama-roller, noma amaketanga epulasitiki ahlanganisiwe. Amandla adonsela phansi noma ama-mechanical drive ahambisa izinto eceleni kwe-spiral.

Umklamo:

Ukuhlelwa okuqondile okuhlangene (isb., izindlela ezijikelezayo ezikhuphukayo/ezehlayo).

Idizayini evulekile yemithwalo yamayunithi (amabhokisi, amaphakheji, imikhiqizo).

Kungafaka izingxenye ezigobile ukuze kusebenze kahle isikhala.

Izicelo:

Ukuphakamisa noma ukwehlisa izinto ezipakishweni, emabhodleleni, noma emigqeni yokuhlanganisa.

Ukuqongelela, ukupholisa, noma ukulungiswa kwesikhathi ezimbonini ezifana nokubhaka, ezokuthutha, noma izikhumulo zezindiza (ukuphathwa kwemithwalo).

Isifinyezo

Ama-screw conveyor ayiziphathi zezinto eziningi ezisebenzisa isikulufu esijikelezayo esijikelezayo.

Ama-conveyor ajikelezayo ayizinhlelo ezisebenzisa kahle isikhala zokuphakamisa/ukwehlisa imithwalo yamayunithi ngendlela ejikelezayo, ngokuvamile zisebenzisa amabhande noma ama-roller.

Ukudideka kuvela emagameni ahambisanayo, kodwa izinhloso zawo kanye nezindlela zawo zihlukile.

Isebenza kanjani ilifti ejikelezayo?

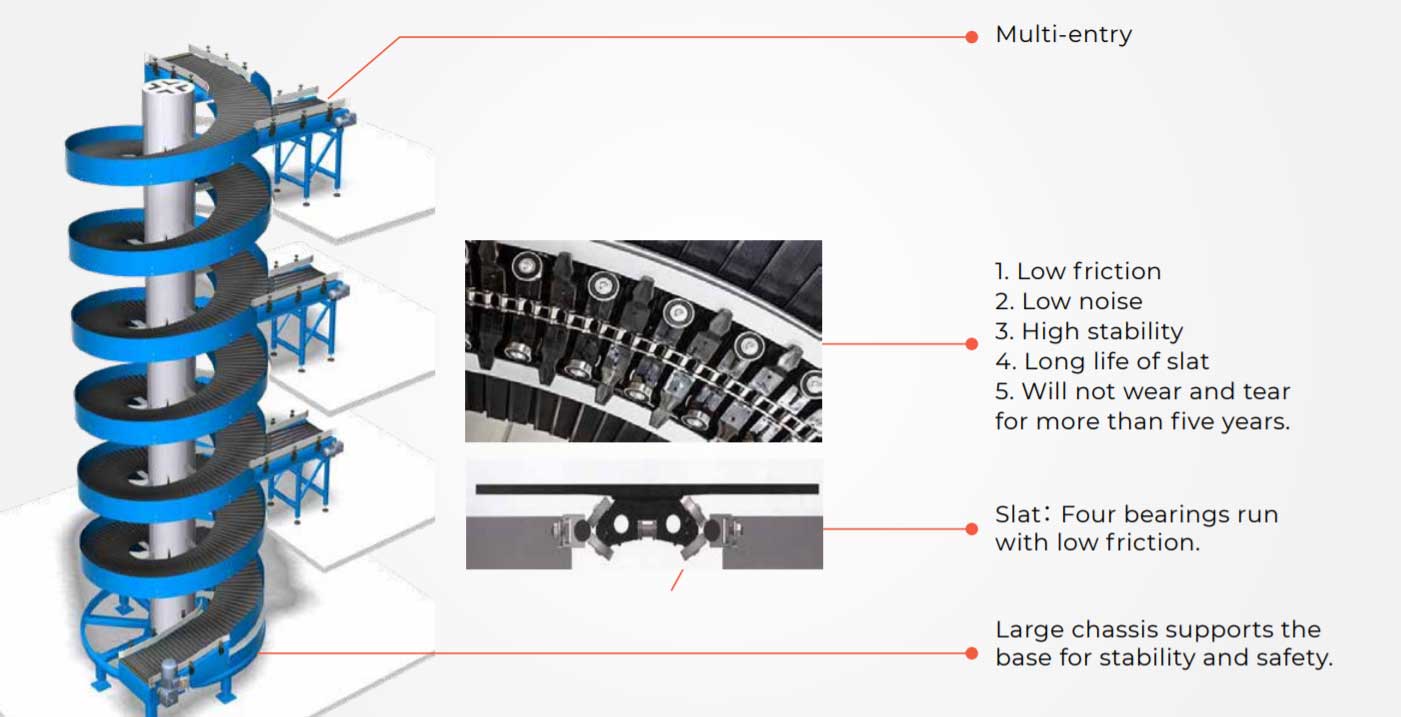

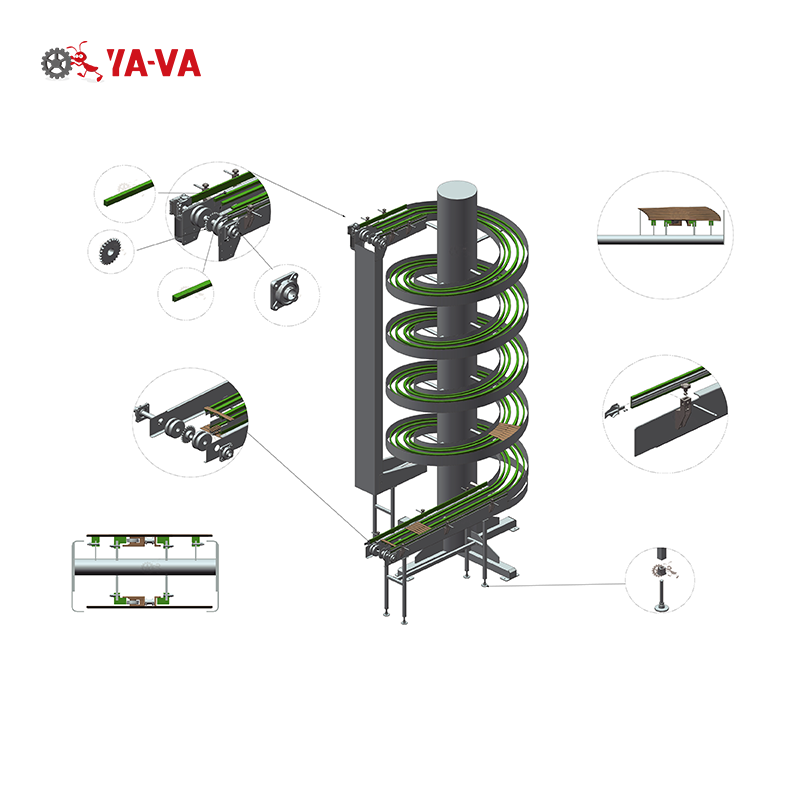

1. Isakhiwo Esiyisisekelo Se-Spiral Conveyor

I-conveyor ejikelezayo ikakhulukazi iqukethe izingxenye ezilandelayo eziyinhloko:

Ithrekhi Ejikelezayo:

Umhlahlandlela noma isilayidi esimise okwe-helix, ngokuvamile esenziwe ngensimbi noma ngepulasitiki enamandla kakhulu, sisetshenziselwa ukuqondisa ukunyakaza kwezinto noma izithwali.

Umthwali:

Amathileyi, amaketanga, amabhande, noma izingxenye eziguquguqukayo ezithwala izinto, eziklanywe ngokwezici zezinto.

Uhlelo Lokushayela:

Idivayisi yenjini, i-reducer, kanye ne-transmission enikeza amandla okushayela ithrekhi ejikelezayo noma ukunyakaza kwenkampani.

Uhlaka Lokusekela:

Isakhiwo sensimbi esisekela uhlelo lwethrekhi ejikelezayo kanye nohlelo lokushayela, okuqinisekisa ukuthi imishini isebenza kahle.

Uhlelo Lokulawula:

Uhlelo lokulawula kagesi olusetshenziswa ukulungisa isivinini, ukuqala nokumisa, kanye nokuqapha isimo sokusebenza kwemishini.

2. Isimiso Sokusebenza Se-Spiral Conveyor

Umgomo wokusebenza we-conveyor ejikelezayo ungahlukaniswa ngezinhlobo ezimbili eziyinhloko: ithrekhi eqondile kanye nethrekhi ejikelezayo.

(1) I-Fixed Track Spiral Conveyor

Isimiso Sokusebenza: Ithrekhi ejikelezayo ayimi, futhi isithwali (njengethreyi noma uchungechunge) sihamba eceleni kwethrekhi, siphakamisa izinto kusukela phansi kuya phezulu.

Indlela Yokuhamba: Isithwali senyuka noma sehla ngomzila ojikelezayo ngokusebenzisa uhlelo lokushayela (njengeketanga noma ibhande).

Izimo Ezisebenzayo: Kufanelekela izinto ezilula nezimile njalo (njengamabhodlela, ukudla okusemathinini).

(2) I-Conveyor Ejikelezayo Ejikelezayo

Isimiso Sokusebenza: Ithrekhi ejikelezayo ngokwayo iyajikeleza, futhi izinto ziyashelela eceleni kwethrekhi ngamandla adonsela phansi noma ukungqubuzana, ziphakama kusukela phansi ziye phezulu.

Indlela Yokunyakaza: Njengoba umzila ujikeleza, izinto zikhuphuka eceleni komzila ngaphansi kwesenzo esihlangene samandla amakhulu kanye namandla adonsela phansi.

Izimo Ezisebenzayo: Kufanelekela izinto ezinkulu noma izingxenye ezincane (njengezinhlamvu, izinhlayiya, izingxenye).

3. Amapharamitha Okuklama Okuyinhloko Kwe-Spiral Conveyor

Ububanzi obujikelezayo:

Inquma indawo yokusebenza kwemishini kanye nomthamo wayo wokuthutha, ngokuvamile eklanywe ngokosayizi wezinto kanye nomthamo wokuthutha.

Iphimbo:

Ibanga eliqondile lethrekhi ejikelezayo ngokujika ngakunye, elithinta isivinini sokuphakamisa sezinto zokwakha kanye nokuphakama kwemishini.

Ukuphakama Kokuphakamisa:

Ukuphakama okuphelele kokuthuthwa okuqondile kwemishini, ngokuvamile kunqunywa ngokwezidingo zenqubo.

Isivinini Sokudlulisa:

Ijubane lokuhamba kwezinto noma izithwali, elithinta ukusebenza kahle kokuthuthwa kwemishini.

Umklamo Wenkampani Yokuthwala:

Isithwali senzelwe ngokwezici zezinto (njengokuma, isisindo, ubuthakathaka) ukuqinisekisa ukuthuthwa kwezinto okuzinzile.

4. Izinzuzo ze-Spiral Conveyor

Ukonga Isikhala: Umklamo ojikelezayo wenza imishini ibe ncane, ifanele ukwakheka kwefektri okunendawo encane.

Ukuthuthwa Okuqondile Okusebenzayo: Kungafinyelela ukuthuthwa okuqondile okuqhubekayo nokusebenzayo, kunciphisa isikhathi sokudlulisa izinto.

Ukuzivumelanisa Nezimo: Umklamo wethrekhi kanye nenkampani yokuthwala ungenziwa ngokwezifiso ngokwezici zezinto ezibonakalayo, ezifanele izimboni ezahlukahlukene.

Ukugcinwa Okuphansi: Isakhiwo esilula, ukusebenza okuzinzile, kanye nezindleko zokugcinwa eziphansi.

5. Izimo Zokusetshenziswa Kwe-Spiral Conveyor

Imboni Yokudla Neziphuzo: Ukuphakamisa amabhodlela, ukudla okusemathinini ngokuma kufakwe emigqeni yokugcwalisa noma emigqeni yokupakisha.

Imboni Yezemithi: Ukuthutha amabhodlela emithi noma amabhokisi okupakisha ezindaweni ezahlukene zokusebenza.

Ukugcina Izimpahla Nokuhlela: Ukuphakamisa nokuhlunga izimpahla ezindaweni zokugcina impahla ezinezitezi eziningi.

Ukukhiqiza Izimoto: Ukuthutha izingxenye ziye eziteshini ezahlukene zokuhlanganisa.

6. Izincomo Zokukhetha Ekwakhiweni Kwezimboni

Izici Zezinto Eziphathekayo: Khetha isithwali esifanele kanye nomklamo wethrekhi ngokuya ngesimo, isisindo, kanye nobuthakathaka bezinto ezisetshenziswayo.

Imikhawulo Yesikhala: Khetha ububanzi obujikelezayo kanye nokuphakama kokuphakamisa ngokwesakhiwo sefektri ukuze uthuthukise indawo yokusebenza kwemishini.

Izidingo Zenqubo: Khetha uhlelo lokushayela olufanele kanye nendlela yokulawula ngokuya ngesivinini sokuthutha kanye nezidingo zokusebenza kahle.

Isifinyezo

I-conveyor ejikelezayo ifinyelela ukuthuthwa okuqondile okusebenzayo ngesenzo esihlanganisiwe sethrekhi ejikelezayo kanye ne-carrier. Umklamo wayo omncane, ukusebenza kahle, kanye nezimo eziningi zokusetshenziswa kwenza kube ngenye yemishini ebalulekile ekukhiqizweni kwezimboni zanamuhla. Onjiniyela bezimboni badinga ukucabangela izici zezinto, izidingo zenqubo, kanye nemikhawulo yesikhala ngokuphelele lapho beklama futhi besebenzisa ama-conveyor ejikelezayo ukuqinisekisa ukusebenza kahle nokuzinzile kwemishini.

Isikhathi sokuthunyelwe: Feb-25-2025