1. Umugqa osebenzayo

Le ncwadi iyasebenza ekufakweni kwe-conveyor ye-aluminium eguquguqukayo

2. Amalungiselelo ngaphambi kokufakwa

2.1 Uhlelo lokufaka

2.1.1 Funda imidwebo yokuhlanganisa ukuze ulungiselele ukufakwa

2.1.2 Qinisekisa ukuthi amathuluzi adingekayo anganikezwa

2.1.3 Qinisekisa ukuthi zonke izinto zokwakha kanye nezingxenye ezidingekayo zokuhlanganisa uhlelo lokuhambisa ziyatholakala, bese uhlola uhlu lwezingxenye

2.1.4 Qinisekisa ukuthi kunesikhala esanele sokufaka uhlelo lokuhambisa

2.1.5 Hlola ukuthi umhlabathi wendawo yokufaka uyisicaba yini, ukuze zonke izinyawo zokusekela zikwazi ukusekelwa ngokujwayelekile ebusweni obuphansi

2.2 Ukulandelana kokufakwa

2.2.1 Ukusaha yonke imigoqo ngobude obudingekayo emidwebweni

2.2.2 Izinyawo zokuxhumanisa kanye nomqadi wesakhiwo

2.2.3 Faka imisebe yokuhambisa bese uyifaka esakhiweni sokusekela

2.2.4 Faka i-drive kanye neyunithi ye-Idler ekugcineni kwe-conveyor

2.2.5 Hlola ingxenye yeketanga lokuhambisa, hlola ukuqinisekisa ukuthi azikho izithiyo

2.2.6 Hlanganisa bese ufaka ipuleti leketanga ku-conveyor

2.3 Ukulungiswa kwamathuluzi okufaka

Amathuluzi okufaka afaka: ithuluzi lokufaka iphini likaketanga, i-hex wrench, i-hex wrench, i-pistol drill.

2.4 Ukulungiswa kwezingxenye nezinto zokwakha

Izibambo ezijwayelekile

I-slide nut

I-nut eyisikwele

i-spring nut

Umugqa wokuxhuma

3 Umhlangano

3.1 izingxenye

Isakhiwo esiyisisekelo sokuhambisa singahlukaniswa ngamaqembu amahlanu alandelayo ezingxenye

3.1.1 Isakhiwo sokusekela

3.1.2 Ugongolo lokudlulisa, ingxenye eqondile kanye nengxenye egobile

3.1.3 Iyunithi yokushayela kanye neyokungasebenzi

3.1.4 Uchungechunge oluguquguqukayo

3.1.5 Ezinye izesekeli

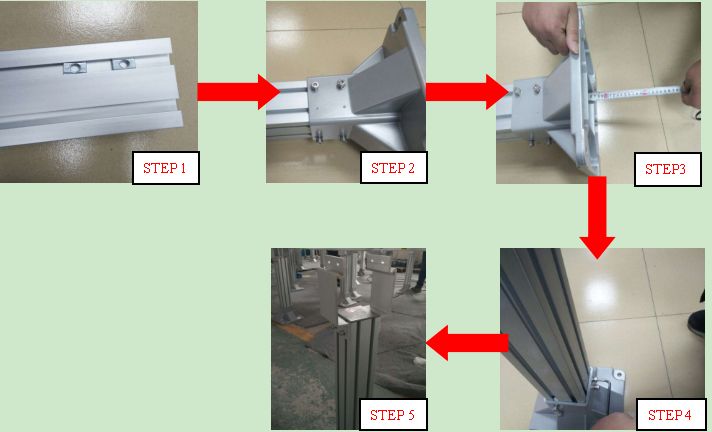

3.2 Ukufakwa kwezinyawo

3.2.1 Faka i-slider nut endaweni engu-T yomqadi wokusekela

3.2.2 Faka ugongolo lokusekela epuletini lezinyawo, bese ulungisa i-slider nut efakwe kusengaphambili ngezikulufo zesokhethi ze-hexagon, bese uyiqinisa ngokukhululeka

3.3.1 Lungisa ugongolo oluvela phansi konyawo lube usayizi odingekayo ngomdwebo, olulungele ukulungiswa kokuphakama ekuhlanganisweni kwesikhathi esizayo

3.3.2 Sebenzisa isikrufu ukuqinisa izikulufo

3.3.3 Faka uhlaka lokusekela ugongolo ngokufaka ipuleti lezinyawo

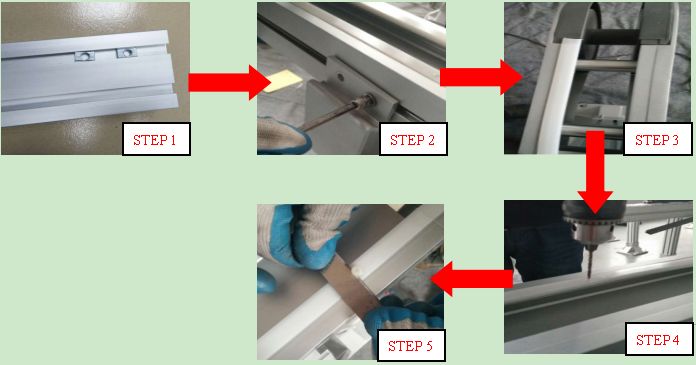

3.3 Ukufakwa komqadi wokuhambisa

3.3.4 Faka i-slider nut endaweni ye-T

3.3.5 Okokuqala lungisa i-bracket yokuqala kanye nogongolo lokuhambisa, bese udonsa i-bracket yesibili bese uyiqinisa ngezikulufo

3.3.6 Kusukela ohlangothini lweyunithi ye-Idler, cindezela umucu wokuguguleka uye endaweni yokufaka

3.3.7 Ukushaya nokuthinta i-wear strip

3.3.8 Faka i-plastic nut bese usika ingxenye eyengeziwe ngommese wokusiza

3.4 Ukufakwa nokususwa kwepuleti leketanga

3.4.1 Qala ukufakwa kwepuleti leketanga ngemva kokuba ukuhlanganiswa komzimba wemishini sekuqediwe, . Okokuqala, susa ipuleti eliseceleni kweyunithi ye-idler, bese uthatha ingxenye yepuleti leketanga, ulifake kusuka kuyunithi ye-idler uliyise emshayweni wokuhambisa, bese ucindezela ipuleti leketanga ukuze lihambe ngomshayweni wokuhambisa ukuze kube yindilinga. Qinisekisa ukuthi ukuhlanganiswa kwe-conveyor kuyahlangabezana nezidingo

3.4.2 Sebenzisa ithuluzi lokufaka iphini leketanga ukuze uhlanganise amapuleti eketanga ngokulandelana, naka indawo yesikhala sobuhlalu benayiloni ngaphandle, bese ucindezela iphini lensimbi epuletini leketanga ukuze libe phakathi nendawo. Ngemva kokuba ipuleti leketanga selihlanganisiwe, lifake emthonjeni wokuhambisa usuka kuyunithi ye-idler, naka ipuleti leketanga Indlela yokuhamba ngayo

3.4.3 Ngemva kokuba ipuleti leketanga lizungeze umzila wokuhambisa ukuze kube yindilinga, qinisa ikhanda nomsila wepuleti leketanga ukuze ulingise isimo semishini ngemva kokuhlanganiswa (akufanele kube kukhulu kakhulu noma kuqine kakhulu), qinisekisa ubude bepuleti leketanga elidingekayo, bese ususa ipuleti leketanga elingaphezulu (ukuhlukaniswa kobuhlalu benayiloni akukhuthazwa ukuthi kusetshenziswe futhi)

3.4.4 Susa i-sprocket ye-Idler bese usebenzisa ithuluzi lokufaka iphini yeketanga ukuxhumanisa ukuphela kwepuleti leketanga nokuphela kwalo

3.4.5 Faka i-sprocket ye-Idler kanye nepuleti eliseceleni elihlukanisiwe, naka ukuthi umucu ongagugi epuletini eliseceleni udinga ukuhlanganiswa endaweni yawo, futhi akunakuba khona into yokuphakamisa

3.4.6 Uma ipuleti leketanga leluliwe noma ezinye izizathu zidinga ukususwa, izinyathelo zokusebenza zibuyela emuva enkambisweni yokufaka

Isikhathi sokuthunyelwe: Disemba 27-2022