1. Ulayini osebenzayo

Leli bhukwana lisebenza ekufakweni kwe-aluminium chain conveyor eguquguqukayo

2. Amalungiselelo ngaphambi kokufakwa

2.1 Uhlelo lokufaka

2.1.1 Funda imidwebo yokuhlanganisa ukuze ulungiselele ukufakwa

2.1.2 Qinisekisa ukuthi amathuluzi adingekayo angahlinzekwa

2.1.3 Qinisekisa ukuthi zonke izinto kanye nezingxenye ezidingekayo zokuhlanganisa isistimu yokuthutha ziyatholakala, futhi uhlole uhlu lwezingxenye.

2.1.4 Ukuqinisekisa ukuthi kunendawo eyanele yaphansi yokufaka isistimu ye-conveyor

2.1.5 Hlola ukuthi umhlabathi wendawo yokufaka uyisicaba yini, ukuze zonke izinyawo ezisekelayo zikwazi ukusekelwa endaweni engaphansi.

2.2 Ukulandelana kokufakwa

2.2.1 Ukusaha yonke imishayo ibe ngobude obudingekayo emidwebeni

2.2.2 Xhuma izinyawo kanye nemishayo yesakhiwo

2.2.3 Faka imishayo yokudlulisa bese uwafaka esakhiweni sokusekela

2.2.4 Faka idrayivu kanye neyunithi ye-Idler ekugcineni kwesidluliseli

2.2.5 Hlola ingxenye ye-chain conveyor, hlola ukuze uqiniseke ukuthi azikho izithiyo

2.2.6 Hlanganisa futhi ufake i-chain plate ku-conveyor

2.3 Ukulungiswa kwamathuluzi okufaka

Amathuluzi okufaka ahlanganisa: ithuluzi lokufaka iphinikhodi, i-hex wrench, i-hex wrench, i-pistol drill.I-diagonal pliers

2.4Izingxenye kanye nokulungiswa kwezinto

Izinsimbi ezijwayelekile

Shelelisa nati

Isikwele samantongomane

i-spring nut

Umugqa wokuxhuma

3 Umhlangano

3.1 izingxenye

Isakhiwo esiyisisekelo sokuthutha singahlukaniswa ngamaqembu amahlanu alandelayo

3.1.1 Isakhiwo sokusekela

3.1.2 I-Conveyor beam, ingxenye eqondile kanye nengxenye yokugoba

3.1.3 Iyunithi yokushayela kanye ne-Idler

3.1.4 Iketango eliguquguqukayo

3.1.5 Ezinye izesekeli

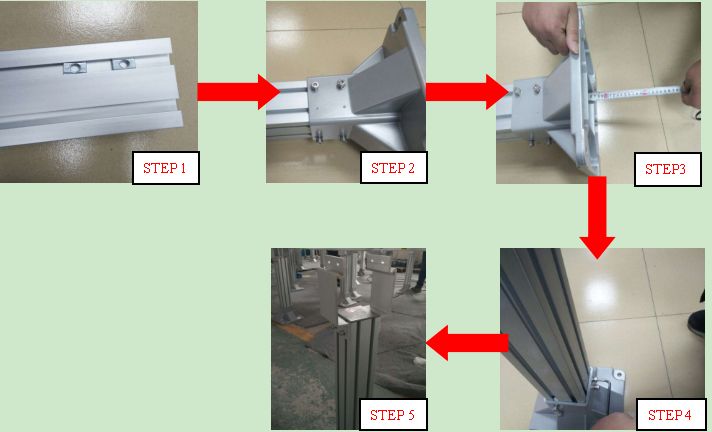

3.2 Ukufakwa ezinyaweni

3.2.1 Faka inadi lesilayidi ku-T-slot ye-beam yokusekela

3.2.2 Faka induku yokusekela epuleti lonyawo, bese ulungisa inathi lesilayida elibekwe kusengaphambili ngezikulufu zesokhethi ye-hexagon, bese uliqinisa ngokukhululeka.

3.3.1 Lungisa induku ukusuka phansi onyaweni ukuya kusayizi odingwa umdwebo, olungele ukulungiswa kobude ekuhlanganiseni okuzayo.

3.3.2 Sebenzisa isikrufu ukuze uqinise izikulufu

3.3.3 Faka uhlaka lokusekela lwe-beam ngokufaka ipuleti lonyawo

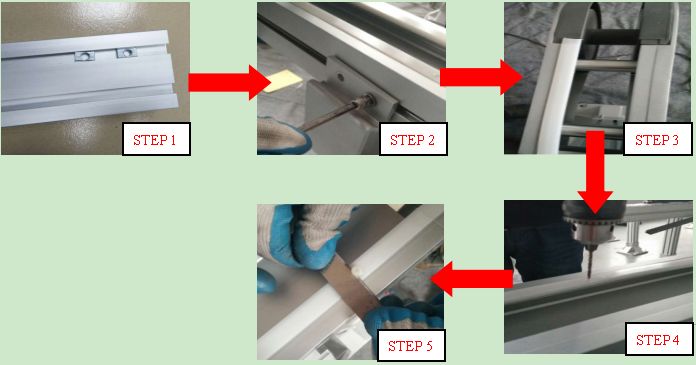

3.3 Ukufakwa kwe-conveyor beam

3.3.4 Faka inadi lesilayidi endaweni ye-T

3.3.5 Qala ulungise ubakaki wokuqala kanye ne-conveyor beam, bese ukhuphula ubakaki wesibili bese uyiqinisa ngezikulufo.

3.3.6 Kusukela ohlangothini lweyunithi ye-Idler, cindezela umugqa wokuguga uye endaweni yokufaka

3.3.7 Ukushaya ngesibhakela kanye nokuthinta i-wear strip

3.3.8 Faka inathi lepulasitiki bese usika ingxenye eyengeziwe ngommese wokusetshenziswa

3.4 Ukufakwa nokususwa kwe-chain plate

3.4.1 Qala ukufakwa kwe-chain plate ngemva kokuqedwa kokuhlanganiswa kwebhodi lemishini, .Okokuqala, susa i-side plate ohlangothini lweyunithi ye-idler, bese uthatha ingxenye ye-chain plate, uyifake kusukela kuyunithi ye-idler ukuya ku-conveyor beam, bese uphusha i-chain plate ukuze ihambe eduze kwe-conveyor beam yombuthano.Qinisekisa ukuthi i-conveyor assembly ihlangabezana nezidingo

3.4.2 Sebenzisa ithuluzi lokufaka iphinikhodi ukuze uhlanganise ama-chain plate ngokulandelana kwawo, unake indawo lapho ubuhlalu benayiloni obukuyo bubheke ngaphandle, bese ucindezela iphinikhodi yensimbi epuleti le-chain ukuze libekwe phakathi nendawo.Ngemuva kokuthi i-chain plate isihlukanisiwe, yifake ku-conveyor beam kusuka kuyunithi ye-idler, unake i-chain plate Isiqondiso sezokuthutha.

3.4.3 Ngemva kokuthi i-chain plate isonge ithrekhi yokuthutha ibe yindingiliza, qinisa ikhanda nomsila we-chain plate ukuze ulingise isimo sezinto zokusebenza ngemva kokuhlanganisa (akufanele ikhululeke kakhulu noma iqine kakhulu), qinisekisa ubude be-chain plate. i-chain plate edingekayo, bese ususa i-chain plate eyeqile (ukuqaqa ubuhlalu benayiloni akunconywa ukuthi kusetshenziswe futhi)

3.4.4 Khipha i-Idler sprocket bese usebenzisa ithuluzi lokufaka iphini lokuxhumanisa i-chain plate ekupheleni

3.4.5 Faka i-Idler sprocket kanye ne-side plate ehlakaziwe, naka umucu ongagugi ku-side plate udinga ukuhlanganiswa endaweni, futhi angeke kube khona ukuphakamisa okuthile.

3.4.6 Uma i-chain plate yeluliwe noma ezinye izizathu zidinga ukususwa, izinyathelo zokusebenza zibuyela emuva kunqubo yokufaka.

Isikhathi sokuthumela: Dec-27-2022